Purpose of the statement

1. The intention of this statement is to encourage consistency by defining what the European Rental Association considers to be best practice in the management and conduct of in-service inspection.

Terminology

2. In this statement periodic in-service inspection is referred to as inspection. Inspection is required by law on lifting machinery (paragraph 4). These inspections provide for the on-going safety of lifting equipment in use.

3. The term employer refers to employers and self-employed.

European Legislation

4. In Europe, the Use of Work Equipment Directive 89/655/EEC as amended by Directive 95/63/EC, Article 4a(2), states the following:

“The employer shall ensure that work equipment exposed to conditions causing deterioration which is liable to result in dangerous situations is subject to:

– periodic inspections and, where appropriate, testing by competent persons within the meaning of national laws and/or practices,

– special inspections by competent persons within the meaning of national laws and/or practices each time that exceptional circumstances which are liable to jeopardize the safety of the work equipment have occurred, such as modification work, accidents, natural phenomena or prolonged periods of inactivity,

to ensure that health and safety conditions are maintained and that the deterioration can be detected and remedied in good time.”

5. The above Directive is implemented in member states by national law and/or guidance.

Purpose of inspection

6. Inspection is intended to:

- verify that the machine is operating as intended;

- identify defects or weaknesses which could compromise the safety of the machine;

- specify the time-scales within which identified defects or weaknesses need to be rectified;

- establish that defects identified in the previous inspection report have received attention;

- assess the correct function of all safety devices;

- check that warning notices are correctly fixed and legible; and

- where necessary, following the inspection, specify any limitations on the use.

Duty holders

Employers

7. Employers have a duty to appoint competent bodies or persons to carry out inspection. They are responsible for ensuring that inspections are carried out and that a current inspection report is available for each item of plant covered by the legislation (paragraph 4).

8. Competent bodies may be employed under contract to carry out inspection at specified intervals. These intervals may be fixed intervals or they may be set on the basis of the competent body or persons’ knowledge and experience (paragraphs 14 to 17). Under these circumstances the employer retains the responsibility to ensure that the machinery is inspected within the specified intervals and that current inspection reports can be made available for examination on request.

Competent bodies and persons

9. Inspection can be carried out by 2nd or 3rd parties. A 2nd party can be a type B or C inspection body and a 3rd party is a type A inspection body under the terms of EN ISO-IEC 17020-2004.

10. Organisations that employ 2nd party competent persons that are maintenance personnel who also carry out inspection should have an independent management structure that supports the competent persons they employ. The management structure should provide for their competence and independence from their other activities when they are involved in inspection activities.

11. The reporting lines within the organisations in which the competent persons work should be identified and be separate from other aspects of work that they are expected to perform that could compete with their inspection duties. Competent bodies and persons carrying out inspection should be capable of meeting EN ISO-IEC 17020-2004, i.e. Criteria for operation of inspection bodies. This means that competent bodies and persons should be able to demonstrate sufficient independence, impartiality and integrity to give confidence that they will carry out their duties in a confidential manner and not be influenced by other competing pressures.

12. Competent persons performing inspection should be capable of detecting defects or weaknesses for the purpose of the inspection. They should have sufficient knowledge, experience and on-going training to assess the importance of defects or weaknesses and to identify what actions need to be taken to rectify them along with necessary timescales for action.

13. Systems should be in place to ensure the quality and consistency of the competent person’s professional development, including their legal, technical and administrative training. This training should include the legal responsibilities of the competent person, how to communicate with clients and what procedures to follow after completing the inspection report.

14. The competent person’s measuring equipment has to be calibrated.

Frequency of inspection

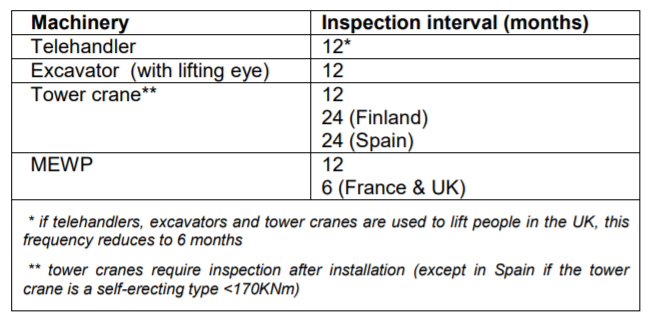

15. The frequency of inspection should be set by the appointed competent body/person taking into account the rate of deterioration of the machinery under the conditions that it is expected to work. Under normal conditions of use, the following frequencies are commonly used:

16. If the competent person judges either by risk assessment or experience that the above intervals are too long because the machinery is subject to a high level of degradation, then the above intervals should be reduced. In addition, there are strong views, based on experience in France and the UK, that machinery used to lift people should be inspected at 6 monthly intervals.

17. Machinery should be inspected to a sufficient extent after it has been exposed to exceptional circumstances or an incident that could affect its safe use and an inspection report supplied.

18. When machinery such as telehandlers, excavators and MEWPs are first supplied (i.e. from new), the manufacturer’s Declaration of Conformity acts as the first inspection. Inspections are then required after the above intervals and, thereafter, at the above intervals. Machinery, such as tower cranes, are required to be inspected after they have been assembled on site and at the above interval thereafter while in use.

Competent person refusing to carry out an inspection

19. A competent person can refuse to carry out an inspection if:

- the equipment has no identification plate or the information on it is indiscernible,

- the equipment is so dirty that it cannot be inspected,

- the equipment has insufficient battery power, fuel or fluid levels to allow it to be tested,

- if access to routine inspection compartments is not possible

- the equipment is in a condition that could cause injury to the competent person or others and/or damage to property.

Reporting inspection

20. An inspection report should be provided following each inspection. The report should contain the information given in Annex 1.

21. It is recommended that a copy of the current inspection report should be kept on the machine or a sticker placed on the machine in an easily visible position to indicate the date for the next inspection.

22. It is good practice to attach a copy of the check list used by the competent person to the inspection report. This check list provides details of the inspection and comments made by the competent person that are in addition to those given on the inspection report. It acts as a statement by the competent person on the scope of their inspection.

How long should inspection reports be kept for?

23. The employer should keep the current inspection report at least until the next inspection report is received. Copies of inspection reports should be placed on the machine file and it is recommended that these reports are kept for the life of the equipment.

24. Copies of inspection reports should be kept by the competent body/person for sufficient time to allow judgements to be made on the appropriateness of the inspection process and intervals used.

25. It is recommended that employers keep data on defects or faults reported by the competent person. This can provide an indicator of the effectiveness of maintenance activities and the frequency of inspection. It is recommended that data should be kept for at least 5 years.

26. MEWPs: In-service records including thorough examination reports should be retained in the specific machine records for the working life of the MEWP. Should the machine be sold then the machine records should be passed on to the new owner. The retention of maintenance records is important in identifying trends as part of any planned preventative maintenance scheme.

Download the full statement at the link below.